Get This Report about Digital Printing

Get This Report about Digital Printing

Blog Article

The Main Principles Of Digital Printing

Table of ContentsDigital Printing Fundamentals ExplainedWhat Does Digital Printing Mean?The Definitive Guide for Digital Printing

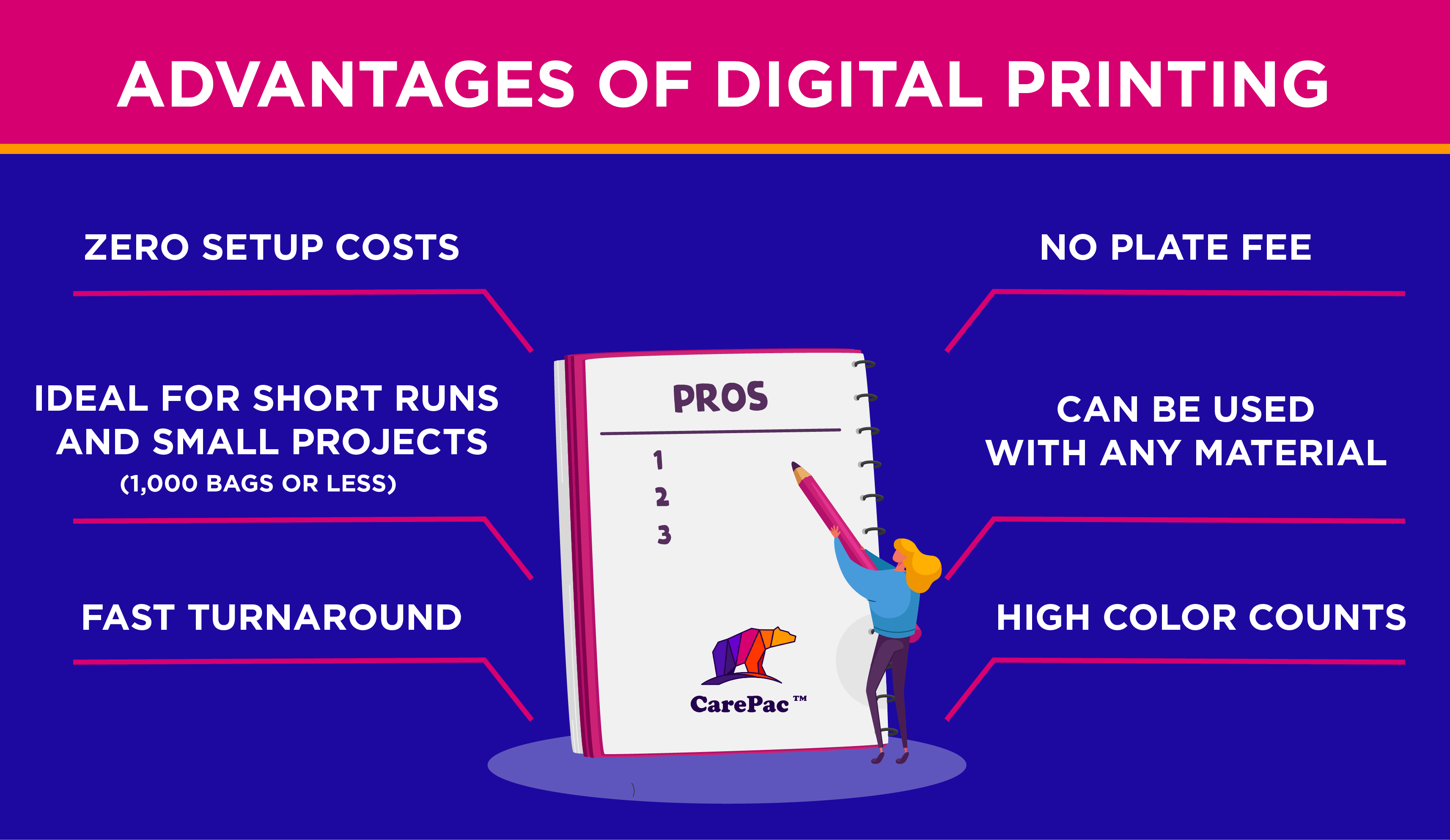

Digital printing additionally needs very little setup. Right here are the key methods in which electronic printing sustains greener practices: One of the considerable ecological benefits of electronic printing is lowering waste (Digital Printing). Typical printing approaches, like lithographic printing, often waste considerable quantities of paper and ink during the setup phase.

Digital printing machine eliminate the demand for these plates, considerably lowering arrangement costs. Digital printing presses can incorporate variable data right into your prints, which enables extremely tailored advertising and marketing materials (Digital Printing). By personalizing your marketing materials, you can raise involvement with potential customers and boost the chances of transforming them into actual consumers

Digital printing presses offer exceptional shade uniformity and accuracy, causing higher quality prints. With electronic printing, you can be certain that the shade of your prints will be regular from one print work to the next. A number of years earlier, several consumers did decline direct-injection digital printing due to the fact that the high expense. The acquisition expense of an established electronic printing tools is at least 150%of the conventional printing and dyeing tools, which enhances the.

Not known Details About Digital Printing

Printers need to make use of extra fluid inks to protect against nozzle clogging and printhead failure. In order to prevent rust of the nozzle, the ink for electronic printing is a lot more pricey than the ink for standard printing, and added ink filtration is essential during the printing process. On top of that, the advantage of electronic inkjet printing is apparent just when utilizing inks with a large shade range. The electronic inkjet printing press nearly realizes the automatic control procedure. In electronic inkjet printing, the pattern is straight published on the fabric, getting rid of home plate making in rotating screen printing. It not just conserves the valuable time of plate production, however also saves the extra cost of plate production. At the very same time, increasingly more brand names are currently increasingly more accepting of paying higher prices for faster distribution, such as supplying a set of materials within a week and even 3 days, as opposed to weeks and months - Digital Printing. Yes, are a lot more costly than conventional printing inks, however the electronic printing process can save ink consumption.

Today, the digital direct-injection printing press has actually gone from proofing to the stage of medium-sized and large-sized pop over to this site production. The digital direct-injection device has actually undergone the promo duration and got in the growth and maturity duration. Both printing homes and brand owners know the development potential of electronic printing, and are prepared to increase financial investment in electronic printing. The print high quality can sometimes also rival that of offset printing. Digital printing is much more affordable for brief print runs because it needs less pre-press tasks and much less configuration than balanced out printing. If a mistake in balanced out printing is not caught before home plates are made, it will be very pricey to make brand-new ones. While everybody truly hopes that mistakes will certainly be prevented, it is practical to prepare for their possible adjustment. Additionally, its accuracy official statement is extremely high. This ensures uniformity in look across the board, decreasing the possibility that any piece will certainly need to be tossed out due to problems. Guaranteeing the plates are in area, the ink trick is calibrated, and all the needed adjustments have been made is a taxing procedure when balanced out printing. Reduced pre-press steps indicate much less time is needed to establish up the press. This causes a marked acceleration of turn-around time. When you require printed materials rapidly, this is a wonderful choice. Digital printing can be a lifesaver when you obtain an order in the nick visite site of time.

Variable information printing, such as direct mail with personalized codes and addresses, is ideally suited for digital printing. Digital fast printing just requires four steps of style, testimonial, printing and binding to get whatever done. Digital fast printing has an unequaled benefit: print on need.

Report this page